Forged steel gate valves are produced to serve our customers top level when they are fully open or closed. With a planer enclosing surface, these various kinds of valves are simple to operate and keep best. Gate valves are mostly generally applied in obstruct related applications. Where fluids should be stopped or complete quickly. forged steel gate valves are so much useful & in industry or market.

Forged Steel Gate Valves are largely in requirement due to their capability to work under cryogenic temperatures. On request a full forcing strength welded joint is applicable. Our range of forged steel valves includes Forged Steel Gate Valve, Forged Steel Globe Valve, Forged Steel check Valve. He is a main manufacturer of forged steel gate valves in Ahmedabad or all over India.

Additional advantages of forged steel gate valves:–

- Designed from one single piece

- Hand wheel managed, strapping in design

- Super Quality

Special Features:

Special Features:

Ball valves manufactured with us are used for gas industry. Mineral industry, petrochemical zone, gas industry etc…

Ball valves manufactured with us are used for gas industry. Mineral industry, petrochemical zone, gas industry etc…

A necessary requirement for the valve to operate is the cracking pressure that opens the valve to enable the medium to flow through. These valves are available in different size and specification as per the requirement of the system. There are different types of non return valves available like spring load, swing type, clapper type, lift-check valve, stop-check valve, in-line check valve and duckbill valve. These valves are used in pumps, chemical plants, power plants, irrigation sprinklers, drip irrigation emitters etc.

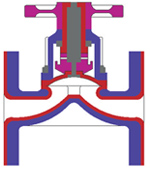

A necessary requirement for the valve to operate is the cracking pressure that opens the valve to enable the medium to flow through. These valves are available in different size and specification as per the requirement of the system. There are different types of non return valves available like spring load, swing type, clapper type, lift-check valve, stop-check valve, in-line check valve and duckbill valve. These valves are used in pumps, chemical plants, power plants, irrigation sprinklers, drip irrigation emitters etc. Globe valves are used for regulating the flow in pipelines. We are manufacturer, supplier and exporter of wide range of globe valves. We use high quality materials in the manufacturing of globe valves to provide best quality product. They are used in that application that requires throttling and frequent operations. We ensure that the working of our valves is smooth and have long durability.

Globe valves are used for regulating the flow in pipelines. We are manufacturer, supplier and exporter of wide range of globe valves. We use high quality materials in the manufacturing of globe valves to provide best quality product. They are used in that application that requires throttling and frequent operations. We ensure that the working of our valves is smooth and have long durability.  Ashwathi Controls Pvt. Ltd.’s Knife Gate Valves are the perfect compliment to our wide-ranging of slurry control products. All our

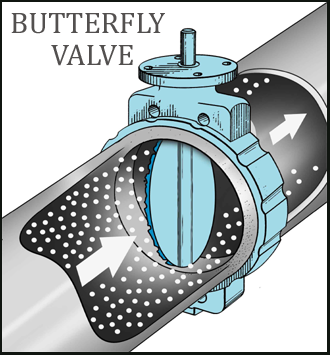

Ashwathi Controls Pvt. Ltd.’s Knife Gate Valves are the perfect compliment to our wide-ranging of slurry control products. All our  flow control device also referred as

flow control device also referred as